Environmental Solutions System

K-FILTER®

More than 1,500 units have been installed in Japan. We propose countermeasures for VOC emissions and reuse of exhaust gas.

K-FILTER® is our proprietary activated carbon fiber that was successfully commercialized for the first time in the world in 1974. It is a highly functional adsorbent that has faster adsorption speed and fewer impurities than granular activated carbon. VOC recovery apparatus using K-FILTER® can recover VOCs such as methylene chloride (lithium battery separator process, etc.) and ethyl acetate (dry lamination, bonding process, etc.) with high efficiency and high purity. In addition, our system is installed as replacing aged granular activated carbon equipment because K-FILTER VOC recovery apparatus can recover high-quality solvents compared to recovery system with granular activated carbon.

Features

This is a device that can recover high-quality solvents with few thermal decomposition components from exhaust gas containing VOCs. We respond to customer needs with over 1,500 units and 40 years of experience.

- Excellent VOC removal performance and high quality solvent recovery

- K-FILTER® achieves higher removal performance than conventional granular activated carbon due to its excellent adsorption and desorption properties. This not only reduces the concentration of VOC emissions, but also allows efficient recovery of high-quality solvents.

- Lightweight, compact and flexible design

- K-FILTER®'s excellent adsorption/desorption performance makes VOC recovery equipment lighter and more compact. We unitize various functions and offer flexible equipment proposals to meet customer needs.

- Excellent safety and adaptability to various gas processing

- The K-FILTER® device has a structure that can be used at normal pressure, so there is little heat accumulation of VOC adsorption, and it is extremely safe. Furthermore, it can be applied not only to general VOC gases but also to the removal and recovery of various gases such as polymerizable monomers and VOCs in industrial gases.

Applications

Methylene chloride in the lithium-ion battery separator manufacturing process, ethyl acetate, toluene, and methyl ethyl ketone in printing and laminating factories, IPA and PGME in semiconductor and liquid crystal factories, methylene chloride, ethanol, and IPA in pharmaceutical factories, alcohol and fragrance ingredients in food factories, and more. recovers various organic solvents such as perchlorene and trichloromethane from groundwater. We also handle the recovery of other expensive solvents used in chemical factories.

Recovery of methylene chloride from lithium-ion battery separator manufacturing process

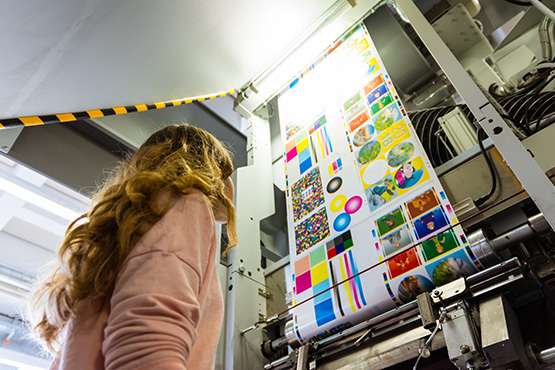

Recovery of ethyl acetate, toluene, methyl ethyl ketone, etc. at printing and laminating plants

Recovery of IPA, PGME, etc. at semiconductor and LCD plants

Recovery of methylene chloride, ethanol, IPA, etc. at pharmaceutical plants

Recovery of alcohol and flavor ingredients at food plants

Recovery of perchloroethylene, trichloroethylene in groundwater

Inquiries about this product

If you have any questions or concerns about our products, please contact us here.

Inquiries by phone

Osaka Head Office Sales Division Environmental Solution Equipment Sales Unit

+81 6-6348-3370

Inquiries by email

ContactEnvironmental solution equipment lineup

Brine Concentration systemHOLLOSEP MINI®

Brine Concentration systemHOLLOSEP MINI® VOC Concentration Apparatus HONEYROTOR®

VOC Concentration Apparatus HONEYROTOR® VOC recovery apparatus (nitrogen desorption type) K-FILTER®

VOC recovery apparatus (nitrogen desorption type) K-FILTER® VOC water treatment apparatus K-FILTER®

VOC water treatment apparatus K-FILTER® VOC recovery apparatus K-FILTER®

VOC recovery apparatus K-FILTER® VOC deodorizer (KR), concentrator (KU)K-MATROLL®

VOC deodorizer (KR), concentrator (KU)K-MATROLL® Catalytic oxidation apparatus, direct combustion apparatus, regenerative combustion apparatus Combustion apparatus

Catalytic oxidation apparatus, direct combustion apparatus, regenerative combustion apparatus Combustion apparatus